Jul 5, 2024

Transforming Wafer Inspection with SPECIM

By integrating Specim’s FX10 and FX17 hyperspectral cameras into the VEpioneer, DIVE has achieved exceptional accuracy and speed in their inspection system solution.

Elsa Reißmann

Strategy & Marketing

DIVE Imaging Systems utilizes Hyperspectral Imaging for precise Surface and Layer Analysis

DIVE imaging systems builds Hyperspectral Vision systems – integrating hardware, software, and comprehensive solutions for industrial inspection tasks. With a primary focus on performance surfaces and thin film applications, DIVE addresses the need for meticulous inspection and quality control in thin-layer application processes. Any deviation from specifications can lead to malfunctions, making accurate assessment crucial. DIVE’s technology offers a comprehensive evaluation of surface characteristics, particularly beneficial in semiconductor manufacturing. Beyond semiconductors, DIVE’s technology caters to a wide range of industries, including electronics production, glass or foil coating for optics, encapsulation, and cleanliness of bonding surfaces.

Innovative Solutions for Industrial Inspection

DIVE offers a fully integrated hyperspectral imaging solution for industrial inspection called Hyperspectral Vision. This solution combines the intuitive one-button VEpioneer® hardware with the user-friendly VEsolve® software.Dr. Philipp Wollmann, CEO of DIVE Imaging Systems, states, “Our goal is to offer a fully integrated hyperspectral imaging solution for industrial inspection, providing comprehensive insights on surface characteristics and layer parameters like thickness, with the aid of artificial intelligence and machine learning.”With DIVE’s solutions, the success of processing steps in semiconductor manufacturing can be tested directly on production wafers, significantly reducing the need for standard test wafers. Specim hyperspectral cameras are crucial in this integration, offering robust, compact designs with GigE connectivity.

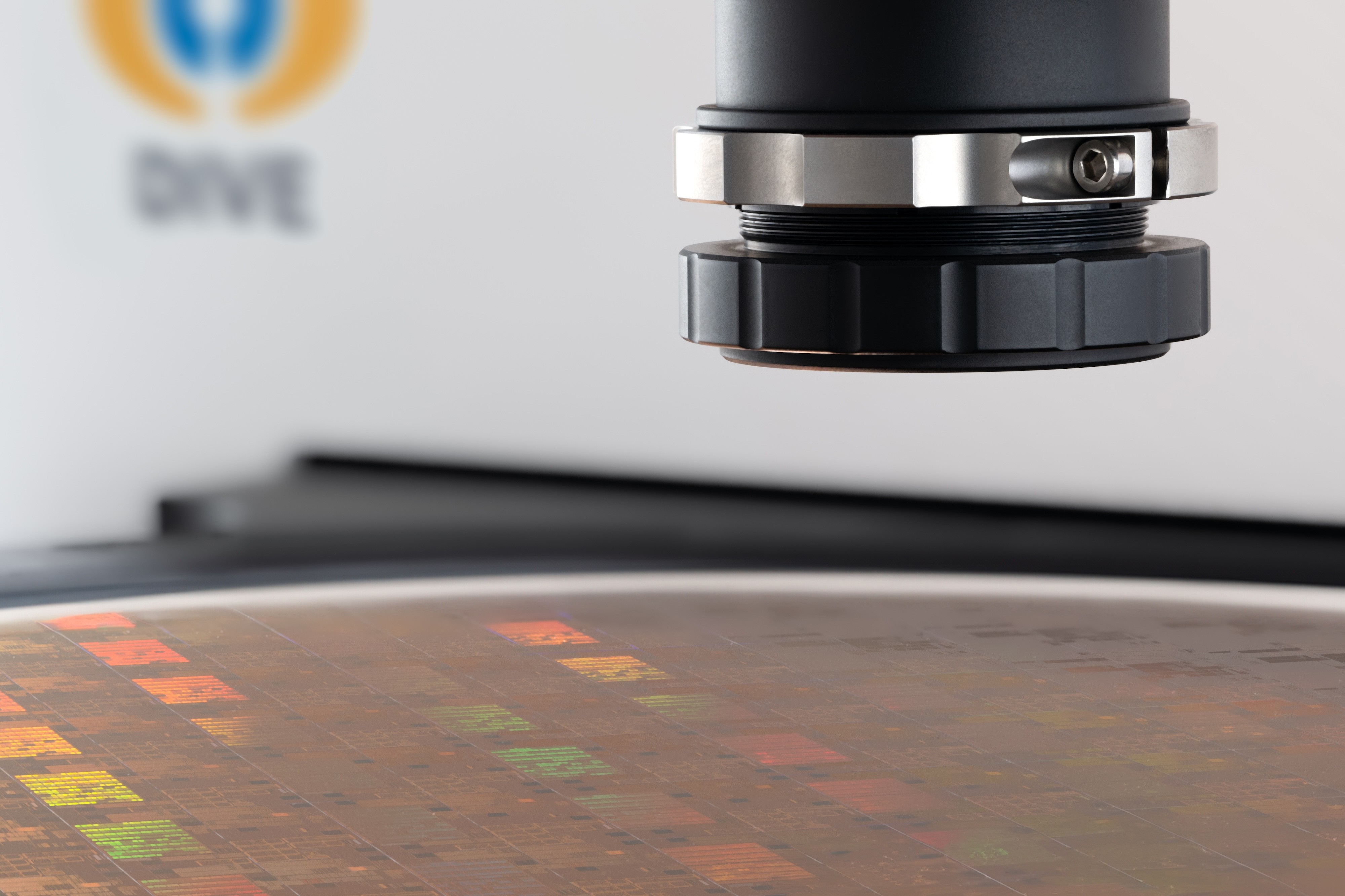

DIVE’s VEpioneer® device for wafer inspection

How Specim Hyperspectral Cameras Enhance Wafer Inspection?

Hyperspectral imaging combines spectroscopy, which provides material and topology information, with imaging for shape and structure recognition, yielding a comprehensive data set. For instance, a layer stack data set can reveal layer thickness distribution, layer composition homogeneity, defect presence and classification, pore detection and quantification, quality classification, and downstream production step quality predictions.In semiconductor manufacturing, hyperspectral imaging evaluates the spatial distribution of thin film thickness of oxides, resists, or surface parameters before or after every processing step in lithography or CVD/PVD/ALD processes. The combination of detailed spectral data with high-resolution imaging enables a thorough analysis of wafer properties, ensuring quality and consistency.

Concrete Benefits of Hyperspectral Imaging in Wafer Inspection

By integrating Specim’s FX10 and FX17 hyperspectral cameras, DIVE has achieved exceptional accuracy and speed in their wafer inspection processes. According to Dr. Wollmann, hyperspectral imaging provides several advantages in wafer inspection over traditional imaging methods:

Non-invasive Measurement: Inspects production wafers without damage.

100% Inspection: Replaces random sampling with complete area coverage, enhancing reliability.

Enhanced Detection: Reveals previously unknown quality-determining parameters.

Increased Throughput: Rapid scanning capabilities increase production efficiency; the scan time of a 300 mm wafer is 30 seconds.

Enhanced Reliability: Improves process design and quality control systems.

Zero Defect Goal: Contributes to achieving zero defects in manufacturing.

Resource Savings: Direct inspection of production wafers reduces costs and waste.

Using Specim FX-series cameras for wafer inspection

Working with Specim

DIVE chose Specim cameras for their robustness, compact size, and GigE connectivity. These features overcame obstacles and provided a modern data interface at a reasonable price. The highlights of working with Specim included fast delivery and comprehensive after-sales support, ensuring seamless integration and operation.

Reduced defect rates, improved product quality, and faster inspection times

The impact of hyperspectral imaging on DIVE’s system was profound. By integrating Specim’s FX10 and FX17 hyperspectral cameras, DIVE achieved unparalleled accuracy and speed in their wafer inspection processes.The Specim cameras enable the detection of contaminants, precise measurement of areal distributions of thin film thickness (resists, oxides, nitrides, and more), and surface condition parameters leading to:

Reduction in Defect Rates: The ability to detect defects at an early stage drastically reduces the number of faulty wafers

Reduction of control wafers: Production control can be performed directly on production wafers, saving materials and tool time.

Improved Product Quality: Consistent and accurate inspections ensure high-quality outputs.

Faster Inspection Times: Increased inspection speed enhances overall efficiency.

New Standard in Wafer Inspection

With hyperspectral imaging, DIVE has set a new standard in wafer inspection, ensuring precision and excellence to maximize product quality. By resolving critical inspection challenges, hyperspectral imaging technology has enabled them to establish an efficient and 100% reliable wafer inspection, improving their partners’ production processes.“The integration of Specim’s hyperspectral cameras has revolutionized our fully integrated hyperspectral imaging solution for industrial inspection. We have seen remarkable improvements in quality and efficiency. Looking ahead, we are excited to leverage this technology further to meet the evolving demands of the semiconductor industry”, Dr. Wollmann states.

Revolutionizing Machine Vision

Dr. Philipp Wollmann believes that hyperspectral vision technology will revolutionize machine vision due to its ability to capture unique, detailed data from hundreds of images. This comprehensive data set is ideal for detecting nuances in industrial processes, far surpassing the capabilities of traditional methods. The integration of machine learning and AI algorithms with chemical-analytical methods allows for unprecedented combinations that offer innovative approaches to assessing product quality.For the first time, it is possible to combine all known image processing methods with chemical-analytical machine learning algorithms and discover completely new approaches to product quality assessment. The global potential for industrial applications of hyperspectral vision technology is vast and nearly limitless”, Dr. Wollmann concludes.

Related Specim Products:

We would like to thank our partners and funding bodies for their support. DIVE is funded by the Federal Ministry for Economic Affairs and Climate Protection and the European Social Fund as part of the EXIST research transfer program (funding reference: 03EUTSN217). DIVE is supported by the European Regional Development Fund and the Just Transition Fund.